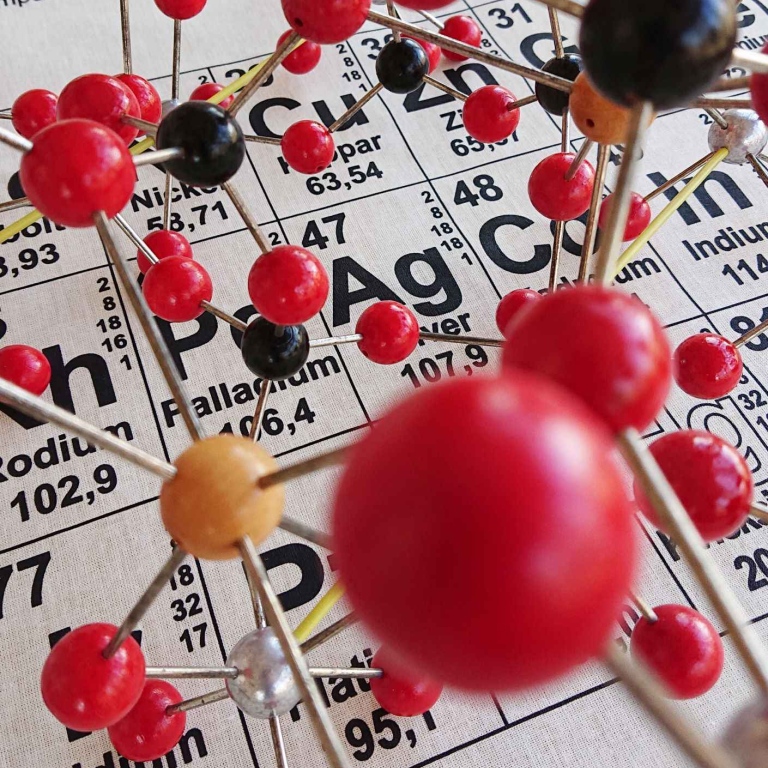

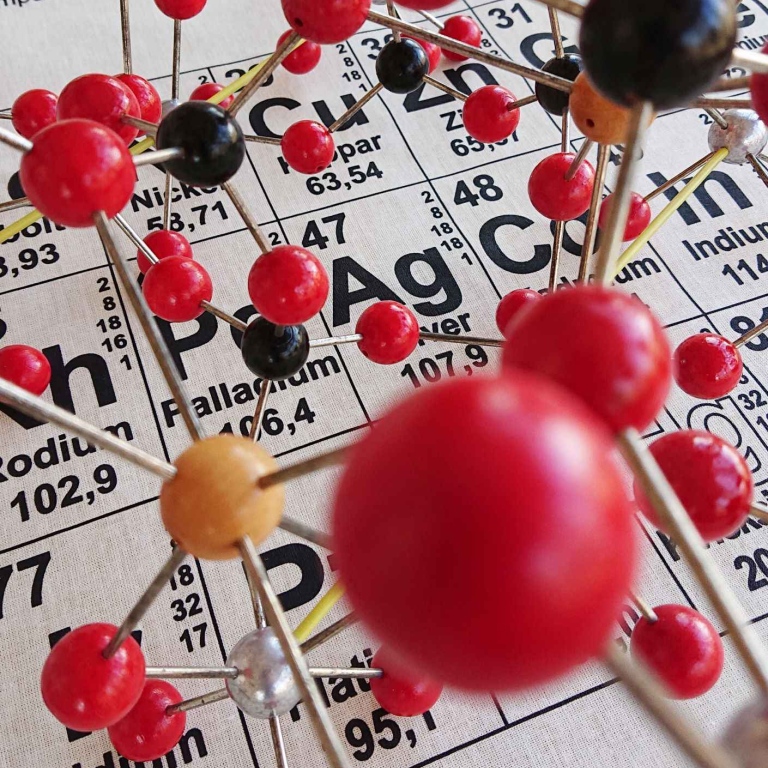

For 50 years, outstanding research and teaching has taken place in the Arrhenius Laboratory. It is named after the first ever Swedish Nobel laurate, Svante Arrhenius, professor of physics at Stockholms högskola (now Stockholm University). This was properly celebrated on Friday November 10th!